Some common factors for Dehumidifier Post Production Inspection:

Appearance

Quantity check

Measurement(weight; size)

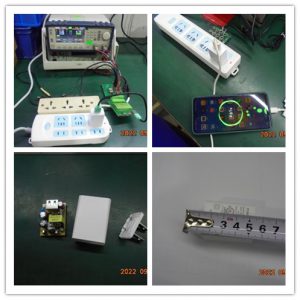

Basic function check

Power test

Electrical safety compliance

Timer function checking

Smart mode test

Humidistat selected between 35-80% check

Humidity indicator check

Intelligent defrost check

Tank full alarm check

Stability test

Power cord pull force testing: 10Kg

Markings durability test

Life test

UV light test

Auto swing function

Roller test

Tank capacity

Overhearting protection test

Water leakages check

Moisture removal and air volume test

Air purifier function check

Internal check

Speed measure(1000±r/min) 230V

Anomaly test

Barcode scan

Drop test

3M tape test for Logo