Some common factors for candle holder quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Smell test

Function test

Dry and wet swab test

Stability test

3M tape test for Logo

Barcode scanning

Carton dropping test

Some common factors for candle holder quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Smell test

Function test

Dry and wet swab test

Stability test

3M tape test for Logo

Barcode scanning

Carton dropping test

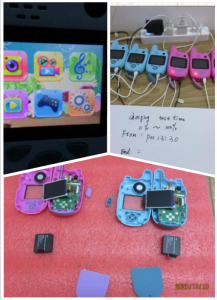

1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Carton dropping test

6.Material check

7.Logo/Printing 3M Tape test

8.Odor test

9.Versions test

10.Setting test

11.Working distance test

12.Discharge test

13.Inner check

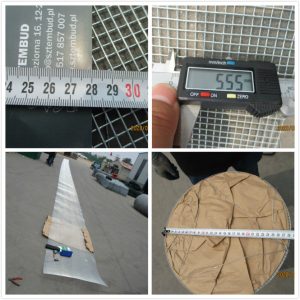

Some common factors for steel mesh quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

3M tape test for Logo

Barcode scanning

Carton dropping test

Some common factors for sharpener quality control:

Appearance

Quantity check

Measurement(weight & size)

Smell test

Function test

Cutter head removable easily or stuck check

Blade hardnes test

3M tape test for Logo

Barcode scanning

Carton dropping test

Some common factors for bone crusher quality control:

Appearance

Quantity check

Measurement

Voltage/Current/Power/Labels

Basic function check

Barcode scan

3M tape test for Logo

Some common factors for Necklace fan quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Basic function check

Working hours after battery fully charged

Charge time(from 0% ~ 100%)

Rub test

360 degrees adjustable

Internal check

Button test switch and 7 colors

Application check

DB check

RPM

3M tape test for Logo

Barcode scanning

Carton dropping test

1.Appearance

2.Quantity check

3.Barcode Scan

4.Material check

5.Basic function check (Assembly)

6.Rubbing test

7.Smell test

8. Leaking test

9. Working pattern check

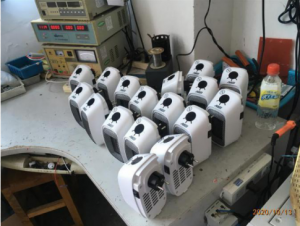

Some common factors for fan heater quality control:

Appearance

Quantity check

Measurement(weight & size)

Hi-pot test

Basic function test

Internal workmanship check

Rub test for rating label & Logo

Running check(5 hours)

Overheating protection test

Handy & spac-efficient for traveling

Noise checking

3M tape test for Logo

Barcode scanned test

Carton dropping test

‘Made in India’ is attractive

Low labor cost is the main advantage of Indian manufacturing. India has always been at the forefront of countries with the lowest labor costs in the world. According to the Bureau of Labor Statistics, the growth of labor compensation (including wages, benefits, social insurance and taxes) in India’s organized manufacturing sector has been very limited for more than a decade, only from 1999. The hourly increase of US $ 0.68 to US $ 1.5 per hour, while the pay of production workers increased from US $ 0.53 per hour to US $ 1 per hour during the same period. The low manufacturing cost, simple operation technology, and high labor intensity make India’s domestic labor-intensive industries such as textiles, clothing, and footwear have great growth potential. At the same time, its manufacturing products are closer to European and American high-end markets in terms of design concepts and sales channels. In addition, Made in India has a place in the high-tech field. Thanks to the relative popularity of English and the relative familiarity with European and American patent systems, Made in India has obvious advantages in biology, chemistry, electronics, and communications, and there is a lot of room for international cooperation.

Since the ‘Made in India’ plan was introduced, it has indeed attracted some overseas investment. Foxconn, the world’s largest OEM for smartphones and electronics, said in August 2015 that the company will open 10 to 12 factories in western India by 2020. At the same time, General Motors announced plans to invest $ 1 billion in developing new models in the Indian market. Some labor-intensive companies that originally invested in China, such as Play-Doh, Monopoly, and Hasbro toy manufacturing industries, are also investing because China is increasingly facing labor shortages Switch to India. Even some Chinese smartphone makers, Huawei, OnePlus, Coolpad and OPPO are planning to produce handheld devices in India; Xiaomi is working with Foxconn to assemble mobile phones in India; Lenovo is planning to cooperate with Flextronics. In this regard, Indian entrepreneurs are full of confidence in the future development prospects of Indian manufacturing. According to B. Muthuraman, President of Tata Steel: ‘In the future, India’s manufacturing industry will also become the world’s leader, just like China.’

The sufficient number of laborers has provided abundant labor resources for Indian manufacturing industry, and also provided favorable conditions for the development of Indian manufacturing industry. However, to replace the leading position of Chinese manufacturing industry, the number of labor force alone is far from enough. At present, India should overcome many problems.

Difficult Indian Manufacturing

Weak infrastructure is a flaw. Weak infrastructure is a flaw in India’s economy and manufacturing. In China, 20% of GDP is used for infrastructure construction every year. A sound infrastructure provides convenient logistics conditions and sufficient energy supply for manufacturing. In India, only 3% of GDP is used for infrastructure construction each year. Long-term debt owed to infrastructure has become a soft underbelly of India’s economy and weakened its development potential.

Traffic system is chaotic. India has not established an efficient and complete transportation system. The road conditions in most areas are very poor and cannot meet logistics needs at all. As the seventh largest area in the world, India has only three major ports. Mumbai, as India’s largest port city, has a population of more than 12 million, but has only one north-south transportation artery. Often it only takes 2 hours for logistics in China and at least 4 hours in India. This forces investors to choose to invest and build factories on high-priced land closer to the port, increasing investment costs.

The power supply gap is large. India’s annual power gap is more than 10%, and it is one of the countries with the lowest per capita power consumption in the world. In August 2012, all three major power grids in India were paralyzed, and large-scale power outages in more than 20 states affected more than 600 million people. The state underinvested in power plants, management was chaotic, power theft and leakage were repeatedly banned, and power system problems often occurred. The limited domestic electricity is not enough to meet the normal living needs of the residents, let alone the electricity required to meet the daily production needs of the factory.

In order to improve the infrastructure, the Indian government plans to invest US $ 1 trillion in infrastructure construction between 2012 and 2017. Five industrial corridors including a large number of highways, railways and telecommunications hubs will be constructed. However, due to the low efficiency of government work, the construction of these projects is still being delayed.

The system is inefficient and the bureaucratic system is difficult to change. There are many limiting factors in India’s current political system. Whatever the political leadership wants to do, it must go through complicated procedures at the central level, and even more complicated approvals in each state. Such a long approval process has greatly lost efficiency and is often used as an inert shield.

India’s laws and regulations are complex and the bureaucracy is serious. For example, there are currently more than 50 central labor regulations and more than 170 local labor regulations in India. These labor regulations are very strict in protecting workers. The Labor Dispute Law, which was promulgated in 1947, requires that companies with more than 100 employees must obtain the consent of the government when layoffs, and when applying to the government for layoffs, they often need to wait for a long and tedious approval process. The possibilities are also remote. The Labor Contract Law, introduced in 1970, requires that companies with more than 20 employees must obtain government approval before hiring contract workers. Given strict restrictions on hiring and firing, most Indian companies have been forced to remain small. A survey by consulting firm McKinsey showed that ‘despite the relevant provisions of the labor law aimed at improving workers’ welfare, they are contrary to their wishes, and most companies prefer not to expand production because of fear of violating labor laws.’

Singapore’s late former prime minister, Lee Kuan Yew, once pointed out:’India used to engage in a state-planned economy, and the scope of state control was too wide, which resulted in the solidification of the bureaucracy and corruption, which wasted decades of development opportunities.’ The status quo is not easy. The strike in India stems from Modi ‘s government’s emphasis on ‘simplifying administration and decentralization,’ hoping to reduce government intervention and rectify bureaucracy. Regarding the employment of enterprises, Modi has decided to amend the Labor Law, suggesting that factories with less than 300 workers can lay off workers without government approval. On the other hand, workers were considered to be infringing on workers interests and faced mass opposition.

The polarization of labor quality is severe. Although India has huge labor resources, however, unlike China’s compulsory education system, India has long pursued elite education, which has led to serious polarization of its domestic labor quality. Usually highly educated workers are reluctant to work in manufacturing industries with poor working conditions and low wages. The uneducated labor force is completely lacking in basic labor quality and cannot meet the labor force requirements of the minimum junior high school education level on the industrial assembly line.

According to a United Nations report, illiteracy in India currently accounts for one third of the world’s illiteracy. The low level of education also makes corporate workers lack the discipline required for manufacturing. Not being on time and not working overtime according to the production needs of the enterprise, which often delays the construction period.

However, manufacturers are often helpless and unable to reduce inefficient labor. In addition to the difficulty in finding workers with certain skills, due to strict labor law restrictions, companies cannot voluntarily reduce workers within the contract period and must apply for government approval. In order to maintain flexibility in employment, manufacturers often only sign temporary agreements with workers. Workers are highly mobile and their skills are difficult to improve. This has also become a vicious circle restricting the long-term development of enterprises and Indian manufacturing.

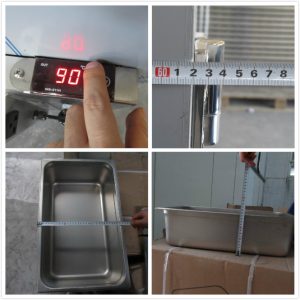

Some common factors for food warmer quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Basic function check

Temperature check

Internal check

Barcode scan

3M tape test for Logo