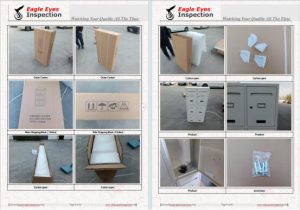

1, Some viewing points: Choose good quality materials, metal, workmanship, spray paint, etc.

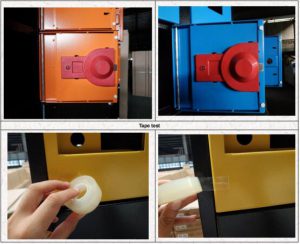

2, Structure, safety, surface treatment, paint adhesion, color consistency, product force, stability (force refers to each force point, stability means that it will not turn forward and fall down).

3, Carefully check the various parts of the product.

4, All connection contacts should be strong, all edges should be smooth without burrs or fragmentation.

5, The material + function test should be done, and the bit should be done, such as durability test.

6, Check that all gaps around the door and drawer are even.

7, Check that all doors are aligned and can work properly.

8, Check that all drawers can be easily opened and closed, and run freely.

9, Check that the top/front/side of the product is flawless, no scratches, and the color of the panel is uniform and matched.

10, All products are customized, the size must be appropriate.

Make sure the surface of the product is smooth and does not have a rough texture

11, The size of the product (mainly length + width + height), if there is time, some other more important sizes are also measured, and the overall quality should be checked.

Please note the defects that may occur in the product;

1. The gaps around drawers and doors are uneven.

2, Doors and drawers do not open and close smoothly and evenly.

3, The door is not aligned.

4,Internal/external finish/paint quality is poor.

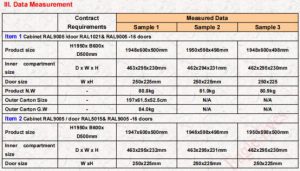

Measured data(Product size,Outer Carton size)

Special test for Mail Box .

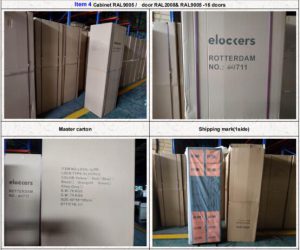

Packing check(color box,out cartons.)

Checking whether the package is fit for transport and meets customer requirements

Inspection Report

The report shows the situation at the inspection site. Check and verify that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.