Thermal paper is also known as thermal fax paper, thermal recording paper, thermal copy paper, in Taiwan is called thermal carbon paper. Thermal paper is a kind of processing paper, and its manufacturing principle is to coat a layer of “thermal paint” (thermal discoloration layer) on high-quality base paper.

Use: as a communication carrier for text and graphics on fax machines, that is, as fax paper; Used as recording materials in medical and measuring systems, such as ECG drawings, thermal instrument recording paper, etc. Printing paper for use in Internet terminals; In terms of commercial activities, it is used to make trademarks, POS, etc., among which the amount of fax paper occupies the largest proportion. Thermal paper is mostly used in commercial supermarkets, gas stations, transportation departments, advertising, tourist areas, enterprises and institutions, and these institutions have a wide range of demands for bills, bar codes, tickets, etc. In some large enterprise units, thermal paper is also one of the common materials for logistics procurement. Thermal paper is an indispensable special paper for modern information processing technology, which has the advantages of fast printing speed, compact and portable printing equipment, low printing noise, no need to change the ribbon, and high clarity for bar code recognition. The national standard for thermal paper is GB/T 28210-2011 “thermal paper”, but in recent years, the rapid development of the thermal paper market, many new products have been developed, GB/T 28210-2011 can not represent the current technical requirements, so many manufacturers in the purchase of thermal paper, will negotiate with the manufacturer to specify the relevant indicators.

Thermal paper is mostly used in commercial supermarkets, gas stations, transportation departments, advertising, tourist areas, enterprises and institutions, and these institutions have a wide range of demands for bills, bar codes, tickets, etc. In some large enterprise units, thermal paper is also one of the common materials for logistics procurement. Thermal paper is an indispensable special paper for modern information processing technology, which has the advantages of fast printing speed, compact and portable printing equipment, low printing noise, no need to change the ribbon, and high clarity for bar code recognition. The national standard for thermal paper is GB/T 28210-2011 “thermal paper”, but in recent years, the rapid development of the thermal paper market, many new products have been developed, GB/T 28210-2011 can not represent the current technical requirements, so many manufacturers in the purchase of thermal paper, will negotiate with the manufacturer to specify the relevant indicators.

What are the detection indicators of thermal paper?

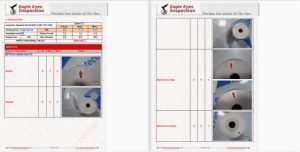

GB/T 28210-2011 According to the technical requirements, the thermal paper is divided into ordinary thermal paper and special thermal paper two products. Their test items are generally quantitative, quantitative deviation, tightness, brightness, smoothness, tensile strength, tear, static color performance, dynamic color performance, image preservation performance, exchange moisture. According to a large number of experimental data provided by Byrnes engineers, the quantitative deviation, tightness, D65 brightness, static color performance, dynamic color performance, and image preservation performance stipulated in the current standard are relatively reasonable, but in the quantitative range, tear degree, tensile strength, smoothness, delivery moisture, image protection of these technical indicators, There are still some differences with the technical requirements of the current thermal industry.

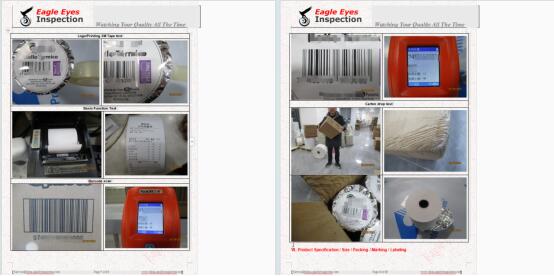

Final inspection can help find some appearance defects of thermal paper.

At the same time, our quality inspection personnel will check the product size, weight, and packaging. Perform special tests on products according to the site conditions and equipment.

Perform special tests on products according to the site conditions and equipment.

Packing check(color box,out cartons.)

Checking whether the package is fit for transport and meets customer requirements.

A professional inspection report will be sent within one working day after the Eagle eyes inspection.

The benefits of choosing Eagle eyes inspection company;

Check whether the goods supplied by the supplier meet the quality requirements stipulated in national regulations or relevant national standards. Timely avoid delivery delays and product defects, and take emergency and remedial measures at the first time. Reduce and avoid consumer complaints, return and exchange of goods and loss of business reputation due to receiving inferior products. Reduce the risk of compensation and administrative punishment due to the sale of inferior products. Verify the quality and quantity of goods to avoid contract disputes.