Some common factors for natural shell decoration quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Simulation assembly test

Color check

Carton drop test

Barcode scan

Some common factors for natural shell decoration quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Simulation assembly test

Color check

Carton drop test

Barcode scan

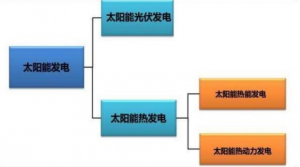

1. Solar energy is the energy from celestial bodies outside the Earth (mainly solar energy). It is the huge energy released by the fusion of hydrogen nuclei in the sun at super high temperature.

2. Fossil fuels such as coal, oil and natural gas are produced by plants that convert solar energy into chemical energy through photosynthesis and store it in plants, which are then formed by plants and animals buried underground over a long period of geological time. Water energy, wind energy, wave energy and ocean current energy are also converted from solar energy.

3. Solar photovoltaic power generation refers to a power generation method that directly converts light energy into electric energy without thermal process. It includes photovoltaic power generation, photochemical power generation, photoinductive power generation and photobiological power generation.

4. Photovoltaic power generation is a direct power generation method that uses solar level semiconductor electronic devices to effectively absorb solar radiation energy and convert it into electrical energy. In photochemical power generation, there are electrochemical photovoltaic cells, photoelectrolysis cells and photocatalytic cells.

5. Solar thermal power generation through water or other working medium and devices to convert solar radiation energy into electrical power generation, known as solar thermal power generation.

6. First convert solar energy into heat energy, and then convert heat energy into electrical energy, two conversion methods: one is to convert solar heat energy directly into electrical energy, such as semiconductor or metal material temperature difference power generation, vacuum devices in the thermoelectric electron and thermoelectric ion power generation, alkali metal thermoelectric conversion, and magnetic fluid power generation; Another way to generate electricity is to use the sun’s heat to drive a generator through an engine such as a turbine, similar to conventional thermal power, except that the heat comes from the sun instead of fuel.

7. There are many types of solar thermal power generation, including the following five main types: tower system, trough system, disk system, solar pool and solar tower thermal power generation. The first three are concentrated solar thermal power generation systems, and the last two are non-concentrated solar thermal power generation systems.

8. At present, the most promising solar thermal power generation system in the world can be roughly divided into trough parabolic focusing system, central receiver or solar tower focusing system and disk parabolic focusing system.

9. The three forms that are technically and economically feasible are: focused parabolic trough solar thermal power technology (referred to as parabolic trough); Focus on central receiver solar thermal power generation technology (referred to as central receiver); Point focusing parabolic disk solar thermal power generation technology.

10. In addition to the above mentioned traditional solar thermal power generation methods, new fields such as solar chimney power generation and solar pool power generation have also made progress.

11. Photovoltaic power generation is a technology that converts light energy directly into electrical energy by using the photogenerating volt effect of semiconductor interface. It is mainly composed of solar panels (components), controllers and inverters, and the main components are composed of electronic components.

12. Solar cells can be packaged and protected in series to form a large area of solar cell modules, and then combined with power controller and other components to form a photovoltaic power generation device.

13. Photovoltaic power generation is a small category of solar power generation, including photovoltaic power generation, photochemical power generation, photoinductive power generation and photobiological power generation, and photovoltaic power generation is only one of the solar power generation.

Some common factors for birth bear quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Compare with sample

Drop test

Loading test

Rub test

Strength test

Pull test

3M tape test for Logo

Some common factors for knitwear quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Odor test

Fitting test

Rubbing test

Seam strength test

Washing test

3M tape test for Logo

Some common factors for Airfreshener Dispenser quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Assembly test

Smell test

Aging test

Vol. output test

Inner check

Barcode scan

3M tape test for Logo

Some common factors for Keyboard Case quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Color compare

Color fastness test

Zipper assistance test

Hardware function test

Stitching pull test

Smell test

Loading test

Barcode scan

3M tape test for Logo

Some common factors for photo frame quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function test

Perpendicularity check

Humidity test

Smell check

Barcode scanning

Carton dropping test

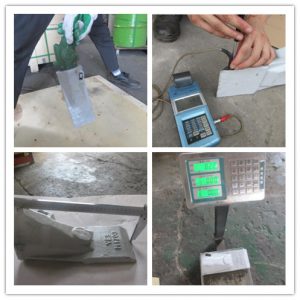

Some common factors for Bucket Tooth and Locking Pin quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function test

Fitting check

Hardness test

Barcode scanning

Carton dropping test

Some common factors for lunch tin box quality control:

Appearance

Quantity check

Measurement

Basic function check

Rub test

Cross-cut test

Loading test(1kg)

Pull test

Fatigue test

Barcode scan

3M tape test for Logo

Some common factors for LED Light-teeth Whiting products quality control:

Appearance

Quantity check

Measurement

Battery charging test

Battery discharge test

Battery voltage test

Product use test

Single drop test

Waterproof test

Key function test

Timing power off test

Magnetic strength test

Inner check

Barcode scan

3M tape test for Logo