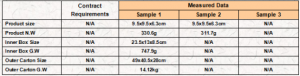

Randomly Selected Samples:

?

Take a look, the tableware to the place where there is a light source to see the refracted light on its surface, if the patterned part and the patterned part refracted light the same, it is inferior, and the reverse is superior. At the same time, it is also necessary to check whether the type is regular and whether the surface has obvious defects; Stack several tableware of the same size together, and if the distance is found to be uneven, it is inferior.

Second touch, touch the patterned and unpatterned parts of the tableware with your hands. If both are equally smooth, it means inferior quality; If the patterned part of the touch obviously has a sense of astringency, the feeling that the pattern is like affixed to the surface of the tableware for excellent products.

Three scraping, the outer layer of tableware is very hard, even how to scrape will not damage the glaze, if found tableware glaze pattern can be easily scraped off, then it must be inferior quality.

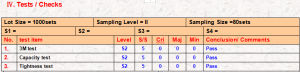

Product quality inspection;

Check the product workmanship, size, size, color, packaging, shipping mark, etc., to confirm whether the product conforms to the customer’s order standards.

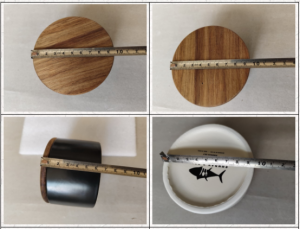

Measured data(Product size,Outer Carton size)

Special test for Ceramic Salt and papper Bowls set of 2

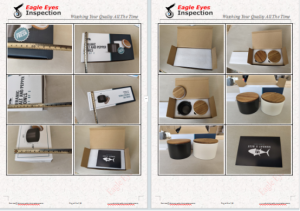

Packing check(color box,out cartons.)

Check whether the package meets customer requirements, determine the size and weight of the package, and check whether the package is suitable for product transportation.

Inspection Report

Eagle eyes quality inspection company will provide inspection report within 24 hours after inspection.The inspection process is checking and verifying that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.