high-heeled footwear、high heels、heels :

stiletto

block/chunky

tapered

blade

cone

wedge

kitten

prism

puppy

spool

court shoes、pumps:

peep-toe pumps。

mules

slingbacks

boots

hip boots、waders

thigh-high boots、thigh-length boots、thigh boots、over-the-knee boots、otk boots

knee-high boots、muckers、fishing boots

chap boots

wedge boots、wedgies

slippers、houseshoes

flip-flops、japanese sandals、jandals or thongs

ballet flats、ballerinas、ballet pumps、dolly shoes、skimmers

platform shoes、disco boots

moccasin

sandals

canvas shoes、sneakers

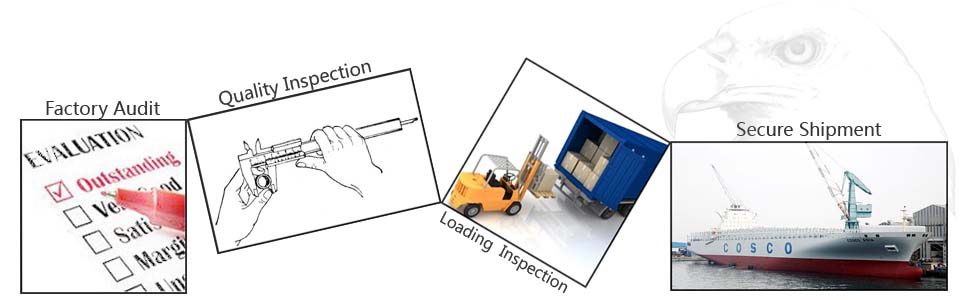

1.Material correspondence checking with material sheet provided by client (upper, lining , insock, outsole)

2.Upper material quality checking:

Wrinkles

Softness

Durability

Checking if the upper leather is dyed after shoe making or its made of dyed leather

3.Lining material quality checking :

Fur quality checking

Leather quality checking

4.Insock checking:

It must be one piece full insock from back to toe

Material must be either cow leather or high quality pig skin

5.Soft Insocks checking :

it must be one piece soft insock from back to toe

6.Outsole durability checking.

7.Visual defects - checking (seam, visual defects, total accurateness)

8.Rubbing test

9.Smell test

10.Color checking with Panton

11.Outsole flexibility

12.Stand test

13.Pulling - shoe durability checking

14.Zipper - quality checking

15.Fitting (wearing the shoe to check its fitting)

16. SHOE BRANDING :

1.Insock logo checking

a) logo size checking (men/women)

b) logo quality

2.Outsole logo emboss

a)logo accurateness

b) logo size

17. PACKAGING

1.Shoe box quality - thickness and accurateness