Some common factors for birth bear quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Compare with sample

Drop test

Loading test

Rub test

Strength test

Pull test

3M tape test for Logo

Some common factors for birth bear quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Compare with sample

Drop test

Loading test

Rub test

Strength test

Pull test

3M tape test for Logo

Some common factors for knitwear quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Odor test

Fitting test

Rubbing test

Seam strength test

Washing test

3M tape test for Logo

Some common factors for Airfreshener Dispenser quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Assembly test

Smell test

Aging test

Vol. output test

Inner check

Barcode scan

3M tape test for Logo

Some common factors for Keyboard Case quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Color compare

Color fastness test

Zipper assistance test

Hardware function test

Stitching pull test

Smell test

Loading test

Barcode scan

3M tape test for Logo

Some common factors for photo frame quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function test

Perpendicularity check

Humidity test

Smell check

Barcode scanning

Carton dropping test

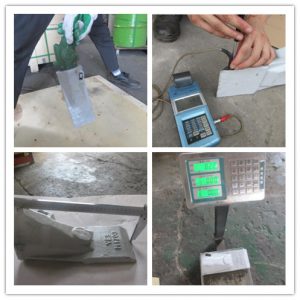

Some common factors for Bucket Tooth and Locking Pin quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function test

Fitting check

Hardness test

Barcode scanning

Carton dropping test

Some common factors for lunch tin box quality control:

Appearance

Quantity check

Measurement

Basic function check

Rub test

Cross-cut test

Loading test(1kg)

Pull test

Fatigue test

Barcode scan

3M tape test for Logo

Some common factors for LED Light-teeth Whiting products quality control:

Appearance

Quantity check

Measurement

Battery charging test

Battery discharge test

Battery voltage test

Product use test

Single drop test

Waterproof test

Key function test

Timing power off test

Magnetic strength test

Inner check

Barcode scan

3M tape test for Logo

1.Logo/Printing 3M Tape test

1.Logo/Printing 3M Tape test

2.Water Leakage test

3.Volume test

4.High temperature test

5.Balance test

6.Hot and cold shock test

7.Rocking on flatness surface

8.Basic function check (Functions on product specification work )

9.Pour water function test

10.Gap check <0.5mm Check

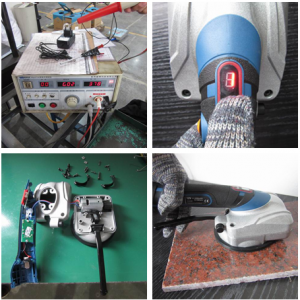

1.Hi-pot check(G-II)

2.Basic function check(G-II)

3.Accessories check(G-II)

4.Smell check(G-II)

5.Full function check(S-3)

6.Internal check

7.Charging time test

8.Discharging time test(no load)

9.No-load speed test

10.Adaptor output current voltage test

11.Power test

12.Noise test

13.Rub test

14.Tape test

15.Battery voltage check after fully charged

16.Application check

17.Barcode scan test

18.Carton drop test