1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Charging test

6.Color comparison

7.Internal check

8.Silicone hardness check

1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Charging test

6.Color comparison

7.Internal check

8.Silicone hardness check

1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Dry/wet rub test

6.Carton dropping test

7.Material check

8.Barcode scanning

9.Water proof test

10.Color abberation test

11.Pull test

12.Leakage test

13.Inflatable test

1.Appearance

2.Quantity check

3.Assembly test

4.Material check

5.3M Tape test

6.Logo/Printing 3M Tape test

7.Rubbing test

8.Odor test

9.Logo/Printing 3M Tape test

10.Basic function check

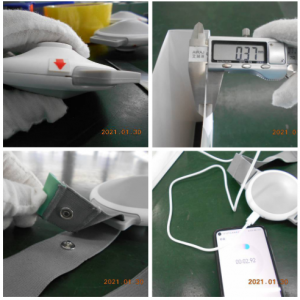

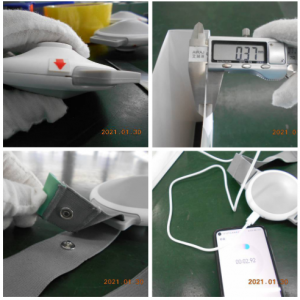

Some common factors for UV sterilization box quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Function test

Assembly check

Internal check

Aging test

3M tape test for Logo

Barcode scanning

Carton dropping test

Some common factors for Sprayer quality control:

Appearance

Quantity check

Measurement(weight& size & thickness)

Basic function check(Functions on product specification work)

Capacity test

Leaking test on certain parts

Barcode scanning

Carton dropping test

1.Appearance

2.Quantity check

3.Carton dropping test

4.Material check

5.3M Tape test

6.Logo/Printing 3M Tape test

7.Rubbing test

8.drop test

9.Fishing rod elasticity

10.Straightness test

11.Weight loading test

1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Internal check

6.Carton dropping test

7.Material check

8.Barcode scanning

9.Water proof test

10.Flame retardant test

11.Elastic pull test

12.Product size/weight check-Disposable mask

13.Sewing stitches per inch(4-5)test

14.Color abberation test

15.Fabric screen printing adhesive strength test

16.Side mesh bag bottle test

17.Fabric dry/wet rub test

18.Fabric screen printing adhesive strength test

Some common factors for marker pen quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Rub & 3M tape test for Logo

Barcode scanning

Odor test

Carton dropping test

1. Logo/Printing 3M Tape and Rub test

2. System version check

3. Memory check

4. Open logo and setting and menu test

5. Discharging test

6. Charging test

7. Camera/Scan Check

8. Wi-fi check

9. Bluetooth check

10. SIM card test

11. MMI Mode test

12. Connect computer test

13. Barcode scan test

1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Dry/wet rub test

6.Carton dropping test

7.Material check

8.Barcode scanning

9.Color abberation test

10.Shaking test

11.Needle detection test

12.Color difference check

13.Stitches check

14.Shaking test