But how can they justify this decision in front of suppliers that have not caused any quality issue in the recent past? We have seen several purchasers in this case, and they know the supplier will take it personally (or will feign to do so). Here is an example of justification:

We have a new company policy. A single quality accident might cost us huge amounts of money, so we will perform quality inspections before every shipment. We trust that you have good management systems in place, and we trust that you are constantly working on improving these systems. However, we need additional safety in the form of external QC inspections.

A third-party inspection firm brings a fresh pair of eyes in the factories. Your people are constantly working on the same products, and sometimes they don't notice issues that will immediately catch the attention of an outsider. Yes, you read right. I believe the main advantage of third-party inspectors (over a factory's internal quality controlers) is their fresh pair of eyes.

And, at the same time, it is a good argument to justify systematic QC without criticizing a Chinese supplier's organization.

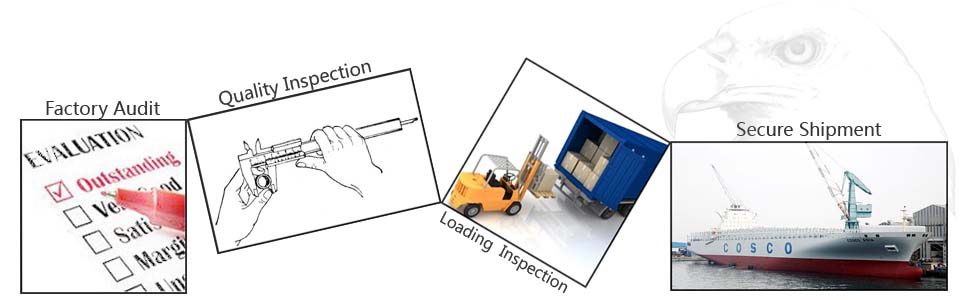

In need of insepction service, Just feel free to drop us an email. Eagle Eyes (CHINA) Quality Inspection Co.,Ltd. will be a good choice for you.